Attention to detail and good workmanship gives you quality concrete flooring.

Floors Take the Maximum Brunt

Flooring is one of the important elements in construction as it is a base for every kind of activity. It is also the one surface that is required to be the toughest when it comes to aesthetics, functionality and maintenance. Hygiene standards are also well connected with the floor.

Concrete floors, either in homes or industries provide an ultra durable surface that can efficiently take loads, wear and tear and have high quality finishes.

CONCRETE FLOORING – THE DO’S

- Right Mix of Concrete – This ensures that you have a strong floor that will not chip or develop other faults.

- Stick To the Structural Design – Hence the concrete floor must be designed for tensile as well as compressive forces acting on it, especially where there are heavy loads.

- Use Standard, Good Quality Materials – Using high quality materials will give you an end product that is of high quality too.

- Good Workmanship – Good materials are a waste without superior workmanship. So ensure you have a skilled team building the floor.

- Proper Concrete Curing – Initial wetting of concrete top surface just when surface starts drying. A properly cured concrete floor gives you durability along with resistant to wear and environmental factors. Skimping on curing time can cause the entire floor to fail.

- Protection of top surface —Protect ,surface with desired finish , form direct exposure to sunlight and prohibiting movement of anyone, over the top.

- Groove cutting in time – Arrange groove cutting within 24 to 48 hours after concreting with panel size not more than 4m X 4m.

- Proper Maintenance – Once the floor is laid and cured, ensuring proper loading, preventing chemical spills and regular cleaning is required.

CONCRETE FLOORING – THE DON’TS

- Not Following Structural Design – This can lead to serious issues like failure of the floor.

- Using Low Grade Of Cement – Using grades other than what is prescribed in the design to save on costs can end up becoming an expensive blunder when one adds demolition and rework costs.

- Not Using the Right Materials – For example using sub standard, untested cement brands can lead to the corrosion of steel in concrete floors, leading to structural failure.

- Unskilled Work – Shoddy work results in issues like honeycombing of the concrete floor when the slurry is not mixed well, uneven floors, improper slopes leading to drainage issues etc.

- Improper Curing – Cracks in the floor, due to improper curing methods or installation are another glaring example of poor work.

HOW TO OVERCOME THE CONSTRUCTION DEFECT

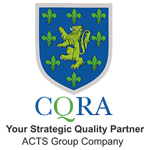

Cracks – Hairline and small cracks can be filled using patching compounds that are easily available in the market. Larger cracks might need interventions of structural engineers.

Uneven Flooring – A floor grinder can be used to level high spots on the concrete floor to match with the average floor level.

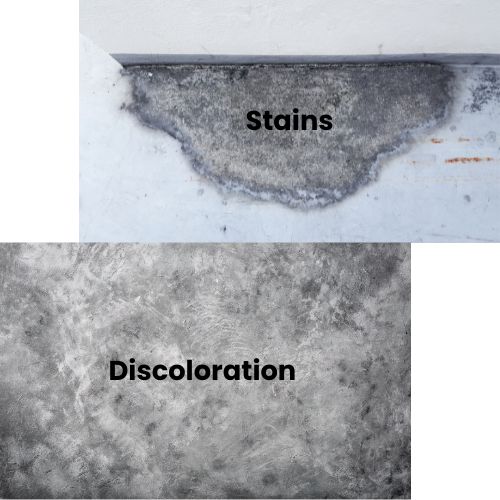

Stains– Concrete floors are highly resistant to stains and chemical spills. However in case your floor stains, prompt cleaning or using special cleaners helps solve the issue.

Discoloration – Improper curing or moisture can cause discoloration of concrete floors but can be addressed by applying a concrete stain.

Dusting – If you see a powdery layer on top of the concrete floor, this is called dusting. Faults in concrete mix and curing process causes dusting. A concrete sealer can help solve the issue or it serious cases, the floor will have to be redone.

Delamination – Excessive water in the concrete mix or over mixing can cause the top layer of concrete to separate from the lower ones. This issue too requires rework.

Quality of your Concrete floor must be your priority. Third Party Agencies like CQRA can help monitor the quality of your floor and other construction processes so that you have a superior and snag free product at the end.