Necessity of Construction Quality

- 6-15% of construction cost is found to be wastage due to rework of defective components detected during maintenance.

- 20-40% of all site defects have their roots in errors arising during the construction phase.

- 54% of the construction defects can be attributed to human factors like unskilled workers.

- 12% of the construction defects are based on material and system failure.

Why Measure the Cost of Quality (COQ)?

- The Cost of Quality ranges somewhere between 15 – 20% of sales, and can be as high as 40% in some organizations.

- To prevent these errors and failure costs from hurting your business’s revenues and profitability you need to know what this means.

- Calculating the COQ within your organization allows you to categorize these costs, find the issues early in the process, and then fix them.

- This, then, eliminates waste and increases profits. It also has the great benefit of pivoting your organization away from control and correction of problems to instead focusing on preventing these issues from cropping up in the first place.

Impacts of Poor Quality

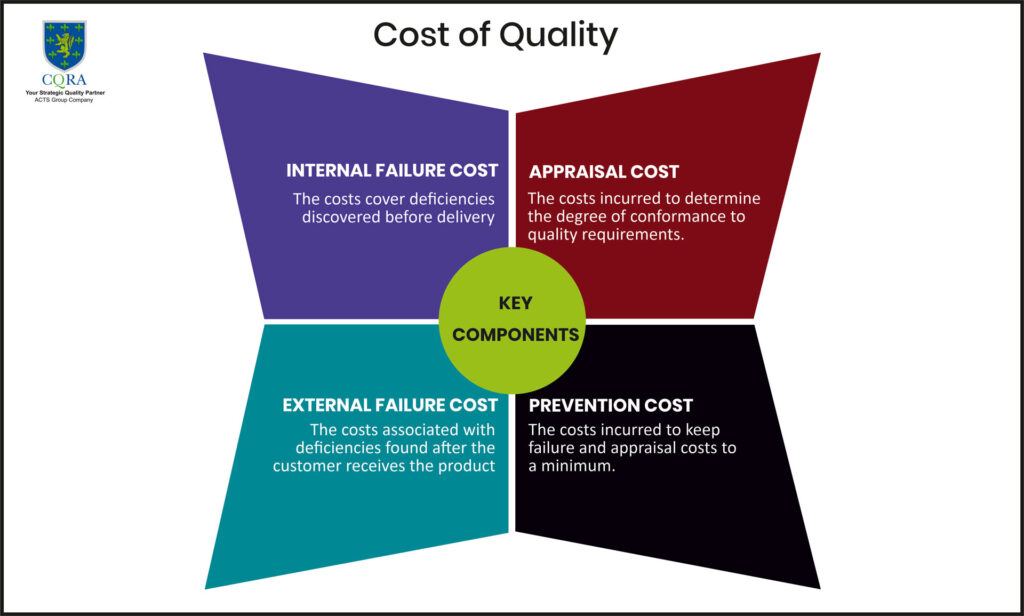

Calculation of Cost of Quality

Cost of Quality (COQ) = Cost of Poor Quality (COPQ) + Cost of Good Quality (COGQ)

Cost of Poor Quality (COPQ)

- Poor Quality can really hurt you. Think about an undetected flaw in the construction which result in latent quality defect.

- Think how much money must be spent to resolve/rectify a quality latent defect, and you can easily see why this is critical to mitigate or resolve.

- There are two categories that factor into the COPQ. Those are Internal Failure Costs and External Failure Costs.

- Internal Failure Costs – (defects occurring and managed within the organization) Scrap, Rework, Re-inspection, Replacement, Loss of yield.

- External Failure Costs – (defects that reach the consumer) Complaints, Loss of Sales, Loss of Reputation, Litigation.

Cost of Good Quality

- These costs contain any controls put in place by the organization and activities to prevent issues in the first place.

- Two categories of COGQ are – Appraisal Costs and Prevention Costs.

- Appraisal Costs (controls put in place by the organization) Inspection (purchased, manufactured), Testing (acceptance, field), Lab Tests Analysis, Field Tests, Quality Audits, Calibration

- Prevention Costs (activities to eliminate defects from occurring)

SPC (statistical process control), Quality Planning, Quality Training, investment in quality-related information systems.

CQRA Value Proposition:

CQRA can help developers to reduce the COQ substantially, particularly COPQ by implementing its state of the art ERP for Quality Management System with prudent on-site management and streamlined construction practices which will result in growth of revenue and profitability.